The Freedom Foamer: Ultimate Touch Free Vehicle Washing Solution

THE FREEDOM FOAMER

Save Time and Labor

Automatic Soap Measuring + Eliminate Refills

This injector automatically dilutes our soaps to the optimum panel impact ratio of 100:1, so you don't have to spend time or energy measuring. This feature is particularly useful in multi-user environments where drivers wash their own vehicles at the end of the day, or for detailers who want to streamline their process and complete more work in the same amount of time.

This is the easiest way to save money and time in your wash bay!

Ultimate Quality

INCLUDES:

- 44" Chem-X Freedom Foamer Lance

- Olight Odin 2000 Lumen Tactical Flashlight

- MTM Hydro SGS35 Squeeze Trigger

- Stainless Steel KEW connects

- Veloci Prima Stainless Steel QC fittings made in the USA

-

Silencer Mode

- ST-75s Foamer w/ KEW inlet for one handed operation

- KEW to QC Adaptor for one handed up close rinsing

-

Suttner ST-164 Two Step Foam Injector

- 18 Metering/Dosing Nozzles for automatic dilution from 12:1 to 200:1 - 2 Packs

- Chem-X Flow Cap 10' Pick Up Tubes

- 2 Gallons Stars + 2 Gallons Stripes

- 10' Jumper Hose w/ QC Fittings

- Directions Panel 10"x15" double sided for both english and spanish (includes double sided tape)

- Replacement Foam Agitator Pad + O-Ring

- 3 Rubber Cushioned Hose Clamps

THIS IS UNLIKE ANY OTHER POWER WASHER INTERFACE

RAIL MOUNTED RECHARGEABLE TACTICAL FLASHLIGHT

Even in the most well-lit wash bays, there is never enough light. With this one-of-a-kind solution, you will never wonder again if you did, in fact, clean your wheel wells thoroughly. Engine bays, undercarriages, and trailer washouts will never be the same.

The OLIGHT Odin Rail Mounted Rechargeable Tactical Flashlight has been load tested in our studio for the last two years without a single failure, living up to our goals of offering durable solutions that are helpful.

MTM Hydro SGS35 TRIGGER

Our favorite trigger option here at Chem-X, the SGS35 features a stainless steel live swivel to maximize efficiency while working. The added fully stainless KEW outlet allows different lance and nozzle attachments and allows rotation under high psi while not sacrificing durability at this junction like conventional QC fittings.

MEZZO VALVE

The MTM Hydro Mezzo Shuttle Valve allows quick easy and durable selection between rinse and foaming functions. The valve allows complete changeover from the high psi rinse nozzle to the slightly lower psi foam nozzle, allowing the remote venturi injection at the ST-164 Injector to draw from your soap containers back at the power washer. This process eliminates refills entirely as well as the need to connect and disconnect foam cannons and rinse nozzles as would normally be the case.

SILENCER MODE

Ideal for small projects or car detailing, this layout allows lightweight one-handed operation and a backup foam or rinse option if the full-length lance were to clog or malfunction while soaping or rinsing a vehicle.

-HIGH END FITTINGS

The Veloci Prima QC line is produced from 303 stainless steel sourced from the City of Steel, Pittsburgh, PA. It is machined to be three times more precise than standard QC fittings, resulting in a longer lifespan and a much higher quality feel. These QC fittings feature the smoothest action in the power washer industry, along with EPDM seals for high temperature and chemical tolerance.

SUTTNER ST-164

DUAL FOAMING CHEMICAL INJECTOR

The most efficient and durable foam injector available, with a dilution range from 12:1 to 200:1. The easiest way to select between two chemicals and rinse. Simply switch the lever on the top of the injector to the desired position(chem 1 or chem 2) and let the soap fly.

This injector also features a full port bypass, which allows full output from the power washer as well as the ability to rinse while in foaming mode, reducing impact for gentile applications like floor mat rinsing.

1. Durable Stainless Steel Construction

2. Injector Inlet - 3/8" QC Plug

3. Injector Outlet - 3/8" QC Coupling

4. Chemical Selection Lever

5. Wall/Surface Mount

6. 18 Dosing Nozzles Included

-

Metering tips control the soap's draw rate. The dosing nozzles have a pin-sized hole through which the soap is drawn; the size of this hole determines your soap-to-water ratio. We install the 0.7 ratio tips for automatic 100 parts water to 1 part soap, or 1% strength, when it arrives to you so that you can get to work without having to think about how the system is set. If you prefer to save costs, these injectors include a 200:1 ratio tip, which would cut soap costs in half per wash, or stronger tips if you find you need to use a more powerful solution in your situation. The dosing nozzles offer a dilution range from 12:1 to 200:1.

STARS AND STRIPES TOUCH FREE WASH

When Stars+Stripes mix on the vehicle surface, a resulting pH shock will activate the cleaning reaction. This dual stage process breaks the static bond of dirt and road film from the surface, allowing the high psi rinse to remove more grime than any single stage application and also results in a neutral pH. This process saves the user up to 80% of the time it would normally take to do a mitt wash. Using two soaps also lets us tackle more grime by allowing us to use a wider range of surfactants that help with many different types of grime.

--

SUTTNER 10' HIGH PSI HOSE - POWER WASHER OUTLET TO INJECTOR INLET

1. 10' Suttner Hose / 6,000 PSI / Abrasion Resistant

1. 10' Suttner Hose / 6,000 PSI / Abrasion Resistant

2. 3/8" Quick Connect Plug

3. 3/8" Quick Connect Coupling

HOW TO INSTALL

1. INSTALL ST-164 INJECTOR ONTO WALL (or MACHINE)

Mount Injector on wall/machine using the provided mounting bracket, with in 10' of power washer. *If you would like the Injector further away or closer to your power washer please call Chem-X with the preferred hose length.

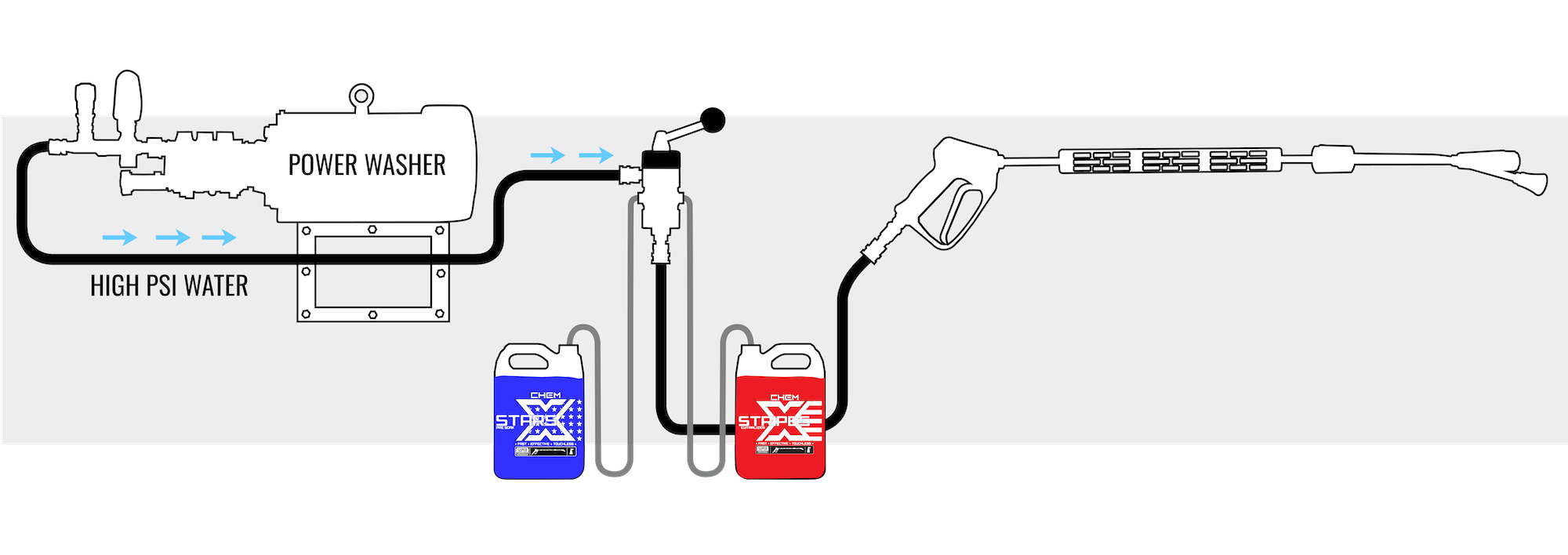

2. CONNECT POWER WASHER TO INJECTOR

Using the provided 10' jumper hose. Attach 3/8" quick connect plug from jumper hose to power washer outlet. Attach 3/8" quick connect coupler from jumper hose to inlet on ST-164.

3. CONNECT INJECTOR TO POWER WASHER HOSE

Plug in your existing power washer hose(or hose reel connector hose) into outlet/bottom of the ST-164.

4. CONNECT POWER WASHER HOSE TO GUN

Plug your power washer hose into the spray gun using the quick connect plug or hard pipe hose directly into Mosmatic DGV Inline Swivel.

5. INSERT PICK UP TUBES INTO SOAPS

Place the left side tube in Stars(BLUE) and right side in Stripes(RED).

-Injector will be set to run at 100:1 unless specified otherwise, this can be changed by simply changing metering tip inside injector barbs.

-If using a hot water machine, scale build up can clog the foam nozzle on the lance. On start up always run lance in rinse mode for about 30-60 seconds to flush out any debris through the rinse nozzle. For systems that see frequent clogs due to coil scale/debris we offer this ST-75 Foam Nozzle which is less likely to clog and can be rinsed.--

-We find the best performance on power washers that start at 2 gallons per minute, and the foam quality improves more and more as you get into 3gpm and 4gpm.

How To Repair Common Issues on Suttner Foam Gear

Specs

CHEM-X FOAM LANCE

- 44" length

- Stainless steel components

- Min/Max Flow Rate: 1-6gpm

- Min/Max PSI: 1000-4000 PSI

- Max Temp: 212 degree *Recommended temp is 125-130 degrees

- Adjustable vented grip

MTM Hydro SGS35 SHUT OFF GUN

- Easy Hold Technology for increased cleaning efficiency

-

Italian manufactured

- Low profile stainless live swivel

- Max PSI: 5000 PSI

- Max Flow Rate: 12 GPM

SUTTNER ST-164 DUAL CHEMICAL INJECTOR

- Max hose length after injector: 150'

- Integrated lever that allows you to easily switch from Stars to Stripes

- Durable stainless steel housing

- 18 metering/dosing nozzles, each chemical can be set at individual desired strengths(comes pre set to run 100:1)

- Min/Max Flow Rate: 1-18 GPM

- Min/Max PSI: 1000-5000 PSI

- Max Temp: 212 degree