Suttner ST-164 Dual Foam Injector

Suttner ST-164 Dual foam injector

The Suttner St-164 is a fully stainless steel dual Chemical injector. Able to be installed by anyone with a few tools and extremely operator friendly. The Injector of choice for any wash bay looking to use Stars+Stripes, our 2 step touchless wash and the only dual injector that works in conjunction with our Chem-X Foam Lance. It's as tough as they come and will hold up running chemicals through it all day.

- Durable Stainless Steel Construction

- Two 10' Pickup Tubes With Chem-X Flow Caps

- Inlet - 3/8" QC Plug

- Outlet - 3/8" QC Coupling

- Integrated Lever

- Wall/Surface Mounting Plate

- 18 dosing Nozzles Included

ULTIMATE DRAW RATE CONTROL

Dosing nozzles control the soap's draw rate. The nozzles have a pin sized hole the soap is drawn though. The size of this hole determines your soap to water ratio. Injector arrives with the correct tips already installed. Dilution range from 10:1 to 200:1.

-

How to operate

1. Swing valve handle to the left for chemical one, apply soap through ST-75 foamer or soaper nozzle.

2. Swing valve handle to the right to select chemical two, apply soap through ST-75 foamer or soaper nozzle.

3. To rinse, switch your lance to high pressure rinse mode. The injector will automatically stop drawing soap.

HOW TO INSTALL

1. INSTALL ST-164 INJECTOR ONTO WALL (or MACHINE)

Mount Injector on wall/machine using the provided mounting bracket.

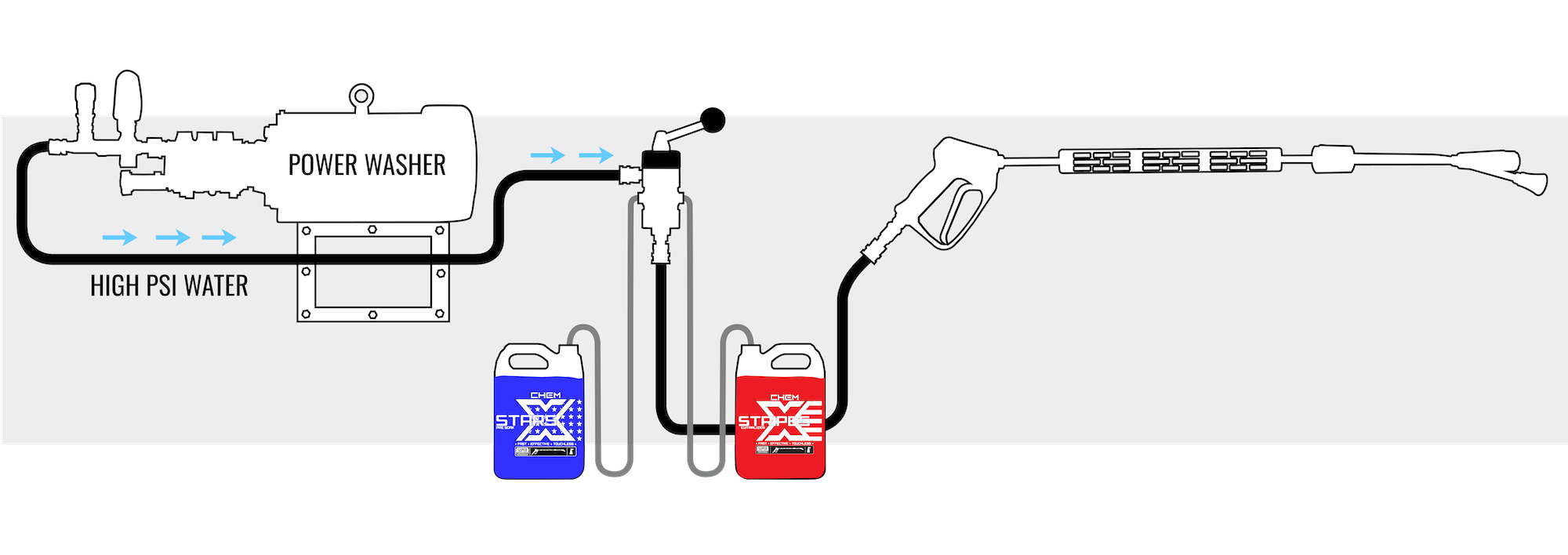

2. CONNECT POWER WASHER TO INJECTOR

Using a jumper hose. Attach 3/8" quick connect plug from jumper hose to power washer outlet. Attach 3/8" quick connect coupler from jumper hose to inlet on ST-164.

3. CONNECT INJECTOR TO POWER WASHER HOSE

Plug in your existing power washer hose(or hose reel connector hose) into outlet/bottom of the ST-164.

4. CONNECT POWER WASHER HOSE TO GUN

Plug your power washer hose into your spray gun using the quick connect plug or hard pipe hose directly into Mosmatic DGV Inline Swivel.

5. INSERT PICK UP TUBES INTO SOAPS

*Injector will be set to run at 100:1 unless specified otherwise, this can be changed by simply changing metering tip inside injector barbs.

-

ST-164/ST-160 Dosing Nozzle RATIO + PERCENTAGE Chart

The chart below shows dosing nozzle size (opening) and the percentage of draw when the chemical used has the same viscosity as water.

SPECS

- Max hose length after injector(when foaming): 150'

- Integrated lever that allows you to easily switch from Stars to Stripes

- Durable stainless steel housing

- 18 metering/dosing nozzles, each chemical can be set at individual desired strengths

- Min/Max Flow Rate: 1-18 GPM

- Min/Max PSI: 1000-5000 PSI

- Max Temp: 212 degree

*Other downstream injectors must be removed from machine before installing the ST-164